Materials

Processes

Design.

Corona Borealis was my final project for Stanford's Computer-Aided Product Creation course – ME318. This product is a small serving platter. In my family we commonly snack on and serve tapas. Maine and Alaska are the two states that we call home and they are both in the northern region where moose live. We enjoy spotting moose out in the wilderness or sometimes even in our backyard. I made this dish for my home and family, drawing a connection from two things that we enjoy. Both the wooden board and the metal antler are organically shaped and highlight a beautiful aspect of the northern wilderness.

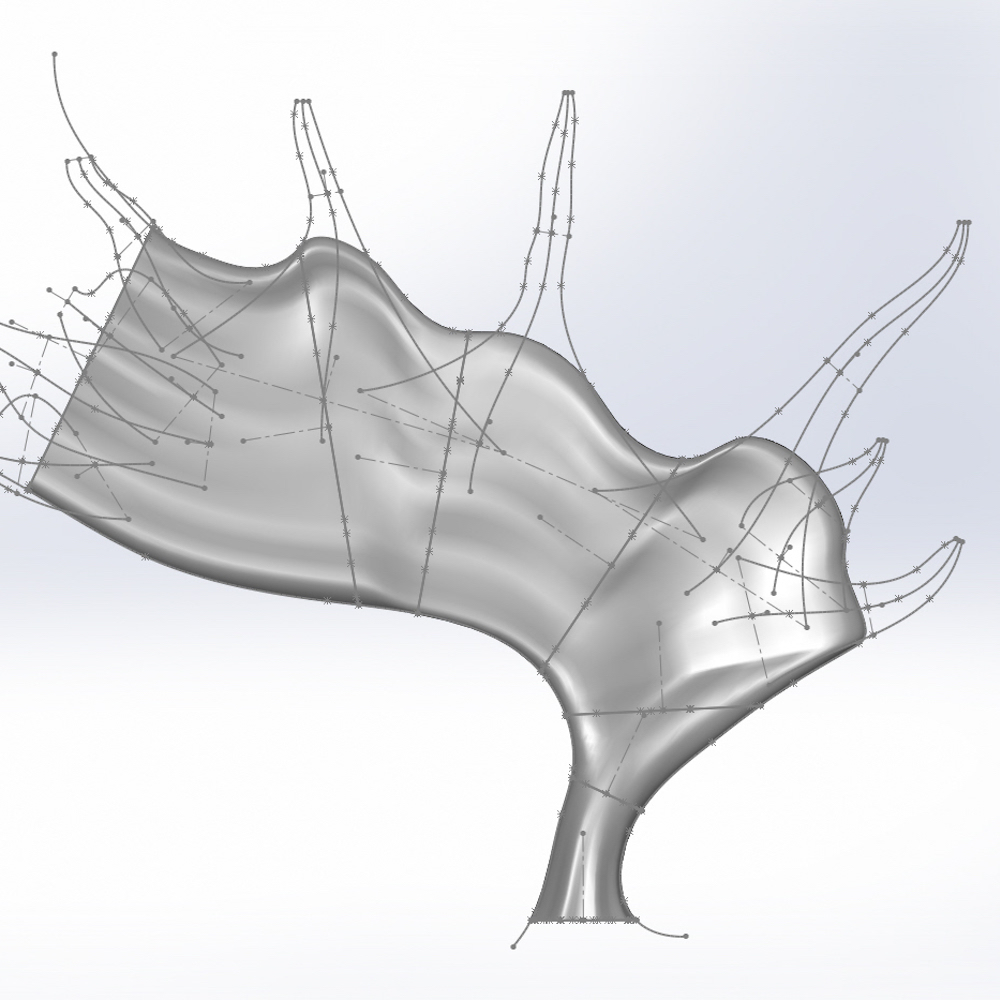

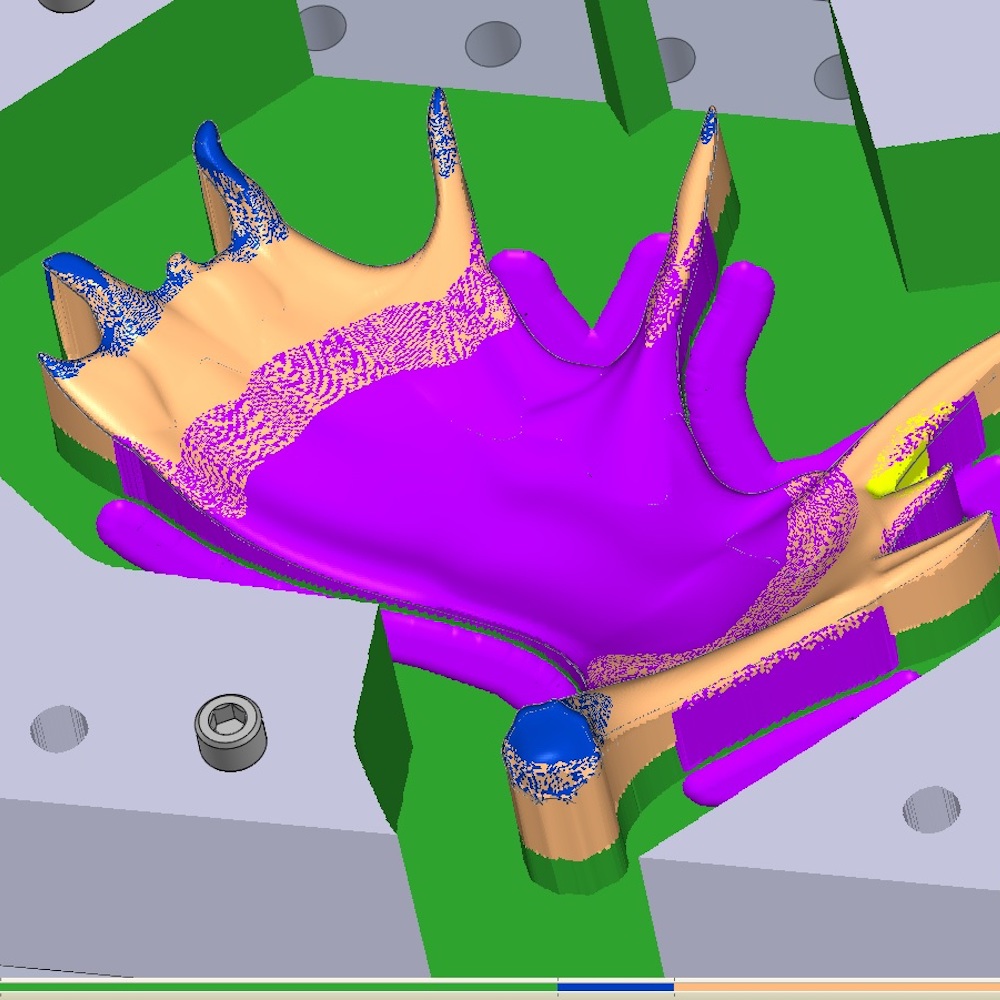

In approaching this project, one of the biggest questions for me was how I would model such an organic shape accurately. After exploring several avenues, I found that intersecting surface lofts for the plate and each horn produced a flat version of what I wanted. The flex feature in SolidWorks then allowed me to bend the antler to a natural curve. Finally, I designed the CAM to only require one part-flip and not leave any tabs.

Manufacturing.

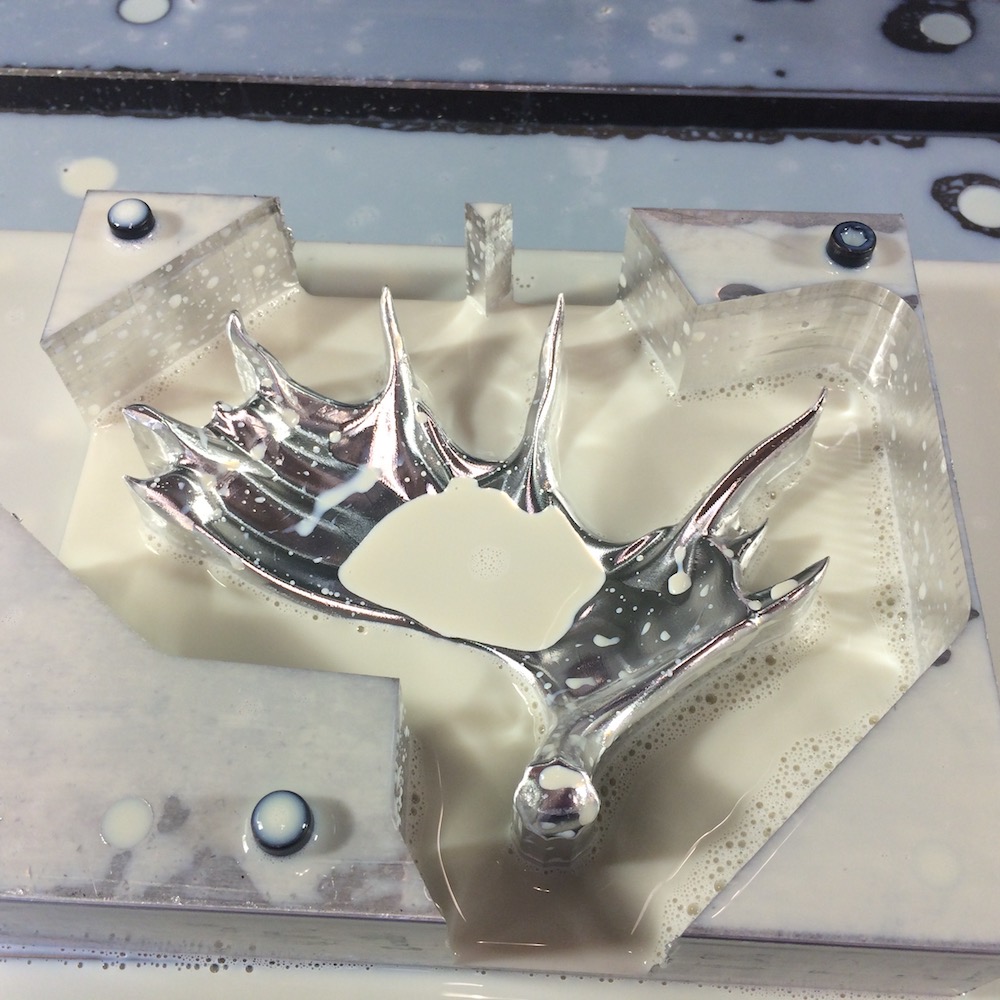

I fixtured and machined the top of the antler first – roughing and finishing. I then filled in the areas that had been machined away with Bondo Body Filler. This allowed me to not require tabs or a thin web. I sanded the Bondo flat and flipped my part to machine the back. I placed my part and Bondo into boiling water and was able to peel the remaining Bondo off. Next, I finished the antler by hand sanding and then clear anodizing.

The board was a perfect project for my introduction to woodworking. I chose walnut because of the hardness and dark color. I made it by wood gluing three boards together, planing and sanding the surface, band-sawing the ovular shape, rounding the edges with a router, hand sanding to get organic feeling edges, and finally finishing with steel wool and then several applications of a butcher block conditioner made from mineral oil and natural waxes.

Gallery.

Sketching in SolidWorks

Visualized CAM

First Milling Job

Filled with Bondo

After Machining

Planing the Walnut